Rules for quality assurance of simulations

The accuracy and meaning of simulation results, depend strongly on the expert knowledge supporting the user during planning, modelling, implementation and evaluation of a simulation. Often, the knowledge is only in the minds of specific individual staff members, stored in files or in paper based documents. This knowledge is frequently difficult to find and inaccessible at the required time for individual users performing a simulation. Missing knowledge, related to quality and safety, which is used as decision criteria in the product development process, can have a particularly negative impact on the product's success. Therefore, the main goal of this project is to collect, prepare and structure knowledge and rules for quality assurance of simulations in a knowledge base. Afterwards the knowledge base is implemented into an assistance system and a quality checklist. These tools provide the users an access to the required knowledge with respect to quality assurance of the simulation quickly and comprehensively.

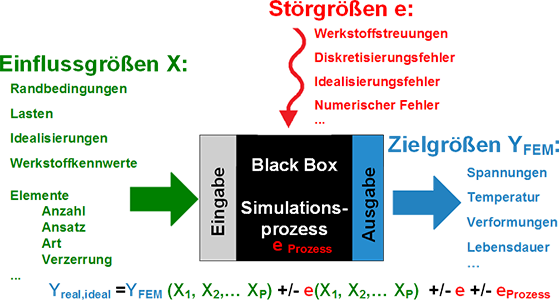

The subproject can be divided into two tasks: Firstly, the quality assurance of functional simulations (e. g. strength and stiffness tests, especially for deep drawing and die-cast parts) and secondly, the quality assurance for process simulations of an exemplary manufacturing process (stamping). For both tasks knowledge is acquired and processed with representations in a digitalized form. In addition to knowledge surveys, another main source of knowledge development in this project is to perform simulation experiments. In these experiments, simulation series are carried out and documented for selected components, products or processes in a systematic test plan considering general quality standards (DIN EN ISO 9001, NAFEMS QSS). The variation of selected simulation parameters such as material characteristics and idealizations, like geometry, load introduction and constraints enables to determine their influence on the deviations and the validity of the simulation results. Simulation experiments thus serve to analyze the influence and interference of influence parameters and disturbance values on the quality of the target simulation. Additionally the simulation experiment can be used to derive rules or procedures. The main aspect of process simulations (FEA and CAM) of the deep-drawing process is the virtual verification of the process with the associated geometric variations. The simulation results are verified either by experimental results or analytical investigations.

Partners from Industry

BMW AG

DYNAmore GmbH

Siemens Industry Software GmbH & Co. KG

PBU CAD-Systeme GmbH