Syngas reactions on metal catalysts

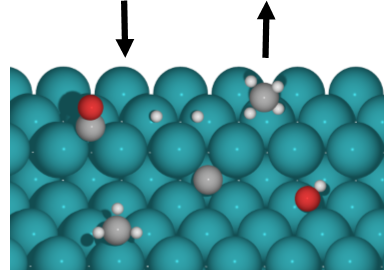

A mixture of carbon monoxide and hydrogen (also known as syngas) is the starting point for many reactions of technological interest in heterogeneous catalysis. The obtained end products are highly dependent on the solid material that catalyses the reaction. Often the catalytically active material is present in the form of nanoscopic particles of transition metals (e.g. Co, Ru, Rh, Ni, Cu or alloys) distributed on a porous support material. In order to tune the activity of the catalyst and the selectivity towards the desired end product (e.g. methane, longer chain hydrocarbons, methanol or ethanol) it is important to gain an atomic-scale understanding of the processes occurring on the catalyst material and their interplay. We study the atomic-scale processes such as adsorption and activation of the reactants, diffusion of reaction intermediates as well as reactions and desorption of products using density functional theory. Through the use of statistical models such as kinetic gas theory or transition state theory, temperature- and pressure-dependent rate constants for the various processes can then be derived. The processes and rate constants can be used as the input for a microkinetic model (either relying on the mean-field approximation or kinetic Monte Carlo simulations) that takes into account the interplay between the various processes and allows to extract macroscopic properties such as catalysts activities and selectivities, which can then be directly compared to experimental data. The obtained insights are useful to elucidate possible reaction mechanisms and can give important leads to the factors limiting the catalyst activity or selectivity.

Read more about our work:

Ang. Chem. Int. Ed. 55, 5210 (2016)

J. Chem. Phys. 146, 040901 (2017)