PDMS-based capacitive pressure sensors

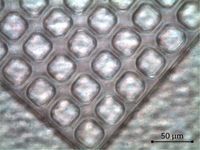

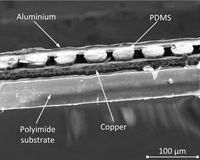

State of the art pressure sensors are in the simplest way based on the piezoresistive principle. A great disadvantage of these sensors is the high dependence on temperature of the piezoresistive effect. With capacitive sensor principles it is possible to resolve that disadvantage. Capacitive sensors based on silicon technology consist usually of a very fragile silicon membrane, which easily breaks at certain pressure levels. The organic elastomere (PDMS) might offer possibilities to resolve that disadvantage. To detect pressure forces with capacitive PDMS sensors it is necessary to develop a novel sensor design and to verify the PDMS technology. New design tools are developed based on adequate models and simulations. Technologies for a productive processing of PDMS are continuingly optimized. The focus of those optimizations lies on the metallization of PDMS. With first samples static and dynamic tests demonstrated that such PDMS sensors are able to detect small and high frequency pressure differences.

- Novel capacitve sensors on elastomere basis

- PDMS as dielectric medium

- Capacity change by outer forces

Fields of Application

- Static and dynamic pressure detection

- Force detection

- Accelerometer applications