Nanocrystalline structures in dual-phase steels

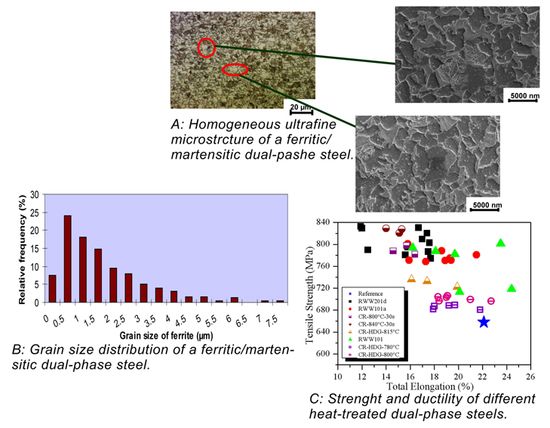

The increasing need for safety of vehicles and the reduction of their weight to improve fuel economy, have lead to the development of advanced low-alloyed high strength steels, such as dual-phase steels (DP), which are known for their attractive combination of strength and ductility. This project is focused on ultra grain refinement of DP steels, which is expected to provide superior mechanical properties. In order to produce ultra fine grained (UFG) microstructures, severe plastic deformation of pre-processed multiphase microstructures takes place, using standard cold-rolling equipment. For this purpose, industrially hot-rolled ferritic/pearlitic material is subjected to pre-rolling heat treatments to produce single phase, dual-phase or multiphase microstructures. The strips are then severely cold-rolled and finally annealed by applying various DP-treatments, leading to the formation of homogeneous ultrafine DP (ferritic/martensitic) microstructures (fig. A). The obtained mean grain size of ferrite grains lies between 1.2-1.4 µm while that of martensite lies between 0.5-1.5µm (fig. B).

Tensile tests have confirmed the beneficial effect of ultra grain refinement on the mechanical properties, showing an increase of 15-25% in tensile strength compared to the reference DP material. The corresponding yield stress remains relatively low (below 400 MPa) and the ductility reaches high values (15-22%, in terms of total elongation), see fig. C.

Currently models are set up to explain the influence of sub-micrometer and nanometer-sized microstructure constituents on the macroscopic material behaviour.